Monday-

Teaching my first session of a new ceramics project at Cumbria Institute of the Arts.

Tuesday-

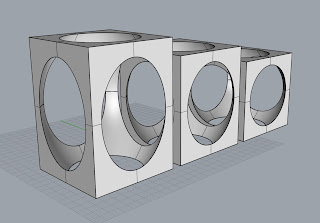

Back to London, the focus of this week is to finish my test pieces in preparation for next week’s tutorial with Martin Smith. I have four cone pieces to fire, one of which cracked during drying, highlighting the hazardous complexity of traditional making techniques on forms where internal access is impossible. I have discussed attempting to press mould a similar cube form, however I suspect that will not overcome the technical difficulties. Slip casting and the post-firing assembly of parts are some of the other ceramic techniques to consider, before investigating alternative materials and RM.

I sprayed both the biscuit fired and dry pieces with a white Hyplas 71 ball clay terra sigillata slip and a leftover demo piece I made at

Ceramic Art London with a black terra sigillata made from our standard black slip recipe.

Wednesday-

Packed the kiln and started the firing.

Thursday-

Unpacked the kiln in the afternoon. Mixed results- the black slip worked very well, but I suspected it would do because of the sheen it developed on application. The white slip is smooth, but very little sheen, it doesn’t look any different from before the firing.

The packet of LED’s, controllers, and transformer arrived from my brother in Austria. I now have the means to put together a simple circuit to produce either white or coloured lights and with further experimentation [and assistance] I should be able to incorporate a proximity sensor to control effects.

In the evening there was an excellent presentation on biomimetics by MADE

[the Material And Design Exchange]. The first part was by Julian George, a material scientist from Imperial College looking into producing synthetic bone structures. He showed examples of biomimetic developments from spider’s webs, lotus flowers etc. Geoff Hollington, a product designer and member of MADE talked about how biomimetics may impact on our lives in the future. Materials that will react in the same way as our senses allow us to are in development and will be part of the not too distant future.

Friday-

I started to prepare a mould for casting cube 4 in glass. The form was designed on

Rhino; I then produced Illustrator files of all its surfaces. These were printed onto adhesive vinyl by plotter/cutter, stuck onto 5mm foamboard and cut out with a craft knife. The internal corners needed to be mitred before assembly. Once assembled, they were used as a model from which to take a plaster/quartz cast.

At lunchtime the research cluster met at Heike’s request to discuss her project. It is always a fruitful experience, the similarities and differences of our projects allowing some fresh perspectives and new information to follow up. For instance, Heike showed a photograph of a piece of glass by Richard Whitely which looks very similar to part of cube 4!

Saturday-

Catching up with things at home- domestic duties, mowing the lawn, checking seedlings etc. All a healthy contrast to London, allowing me some important time to reflect on the week.

Sunday-

The rain has returned after 3 or 4 weeks of gorgeous weather, however I’m packing some of the figures that I made during Easter. My youngest daughter, Grace has an interview at Midddlesex University on Tuesday for a place on the Fashion & Textiles course and Vicky is helping her to complete a Yamamoto top. The pattern was downloaded from the

Showstudio website with very few instructions, so assembly has been a challenge. She is really keen to get a place, however students are asked to leave their portfolios, and after inspection some of the applicants are invited to interview. She’ll be pretty devastated if she doesn’t get an interview, as that is where she will excel.